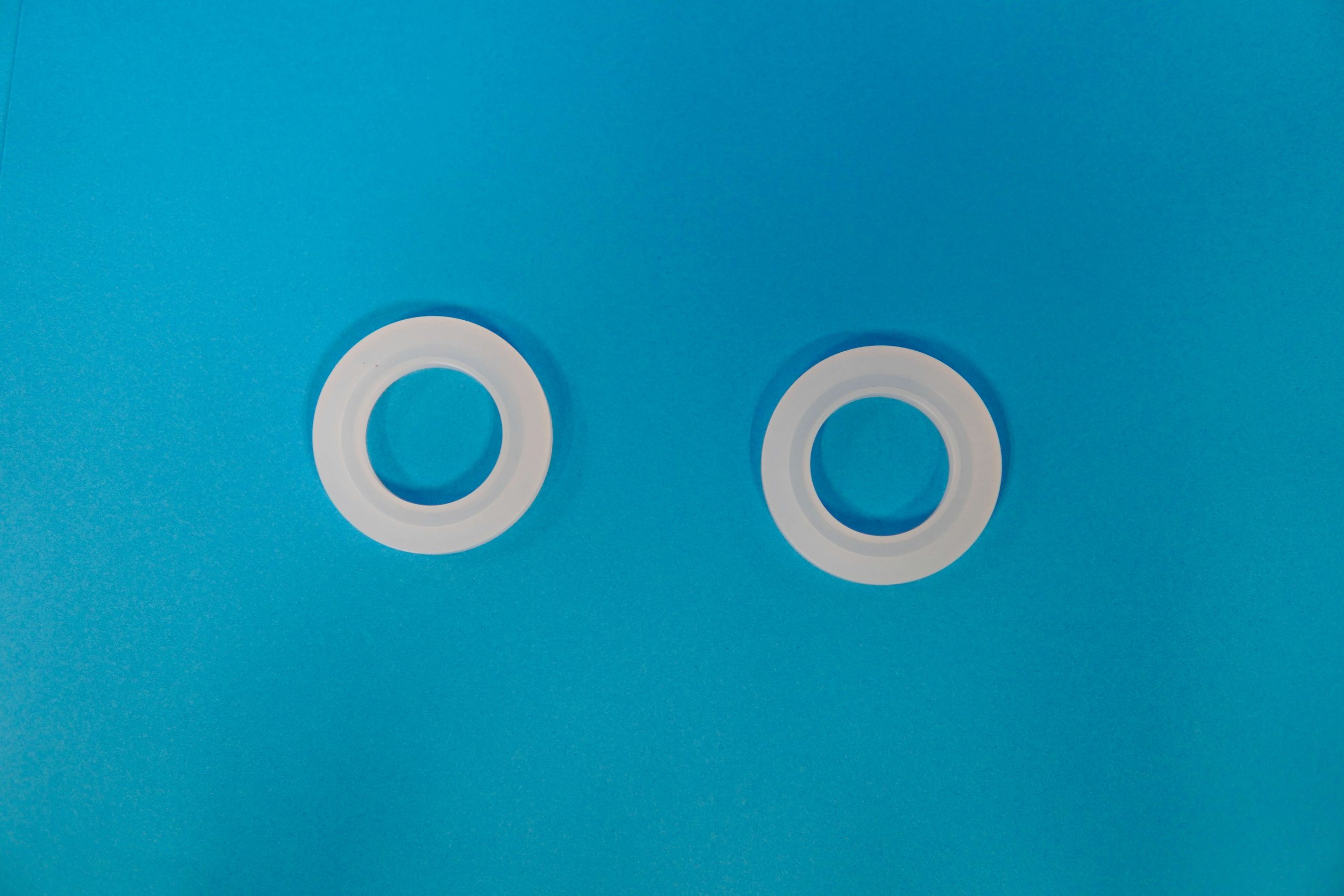

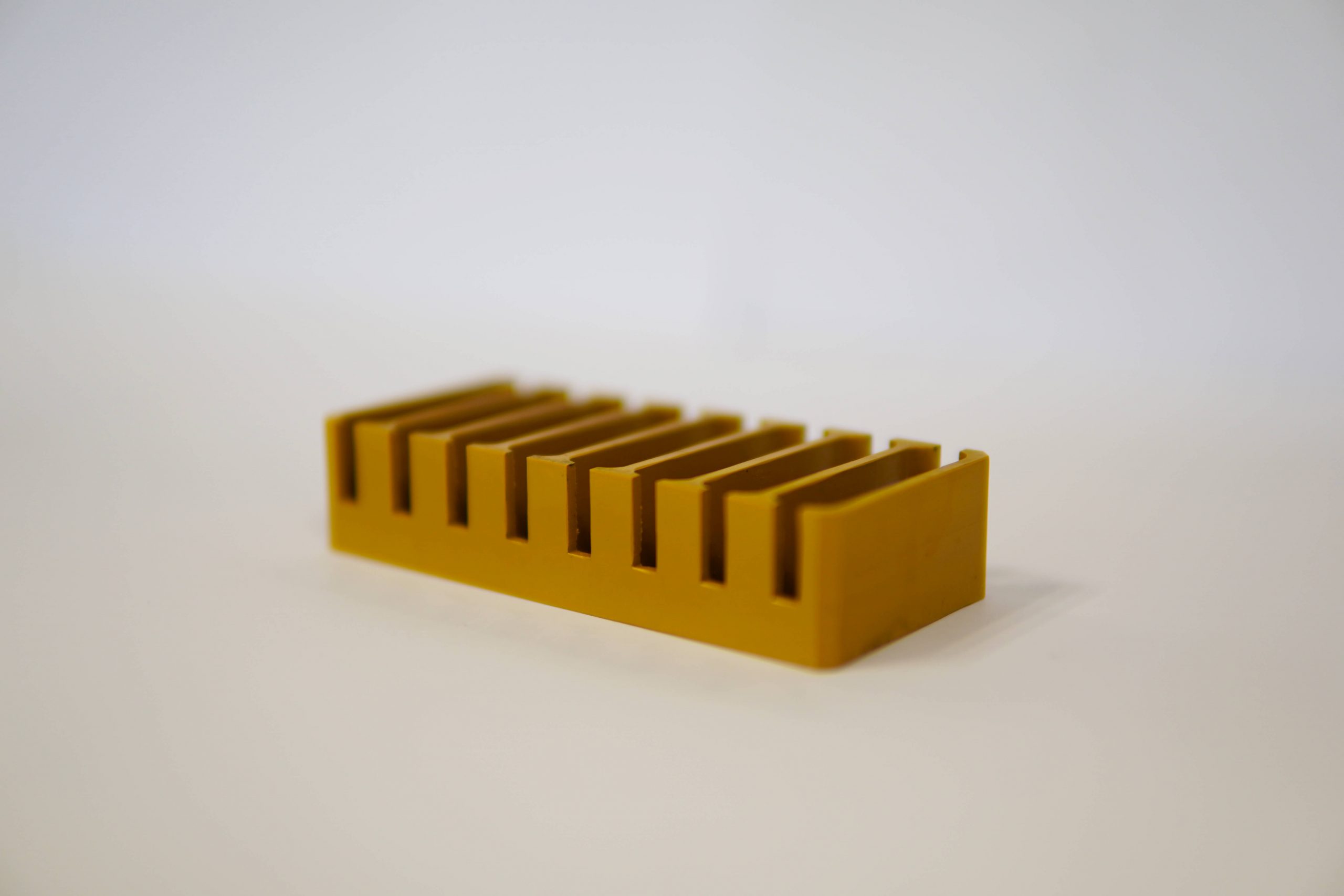

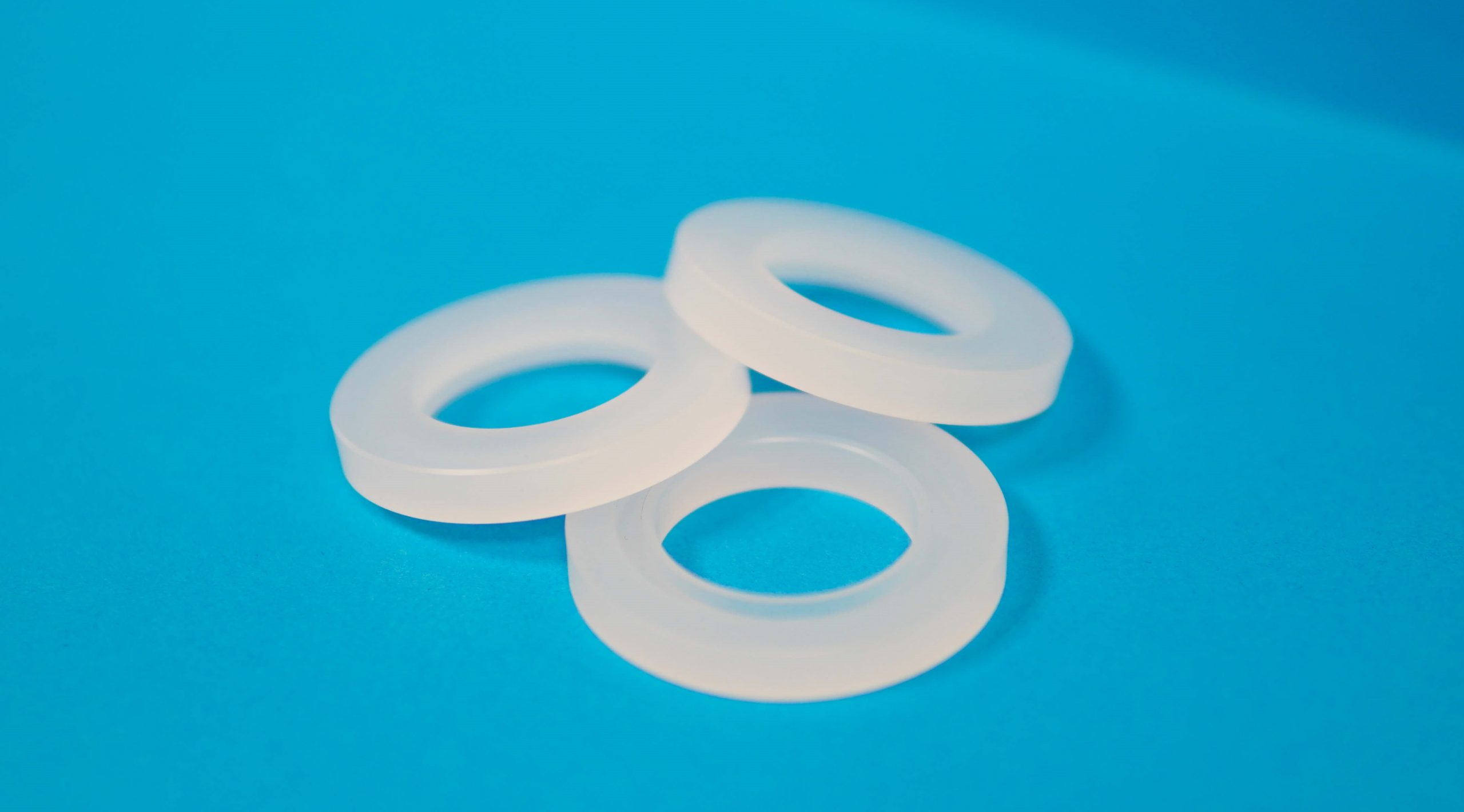

PTFE Turning

PTFE Turning Turning of plastics, including PCTFE or polychlorotrifluoroethylene, is one of SPN's main activities. Turning is a very delicate operation consisting in machining plastic parts by material removal. This technique only concerns parts that have an axis of revolution. To carry out a turning operation, the company uses high-performance...