The processes

SPN has two main competences: the transformation and machining of high-performance plastics. This expertise extends to the following materials: PCTFE, PTFE, FEP, PFA, PVDF, PI – Polyimide, PEI, PSU, PES, ETFE, and PPS.

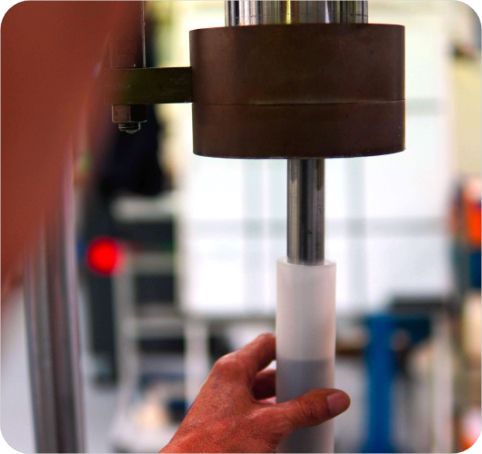

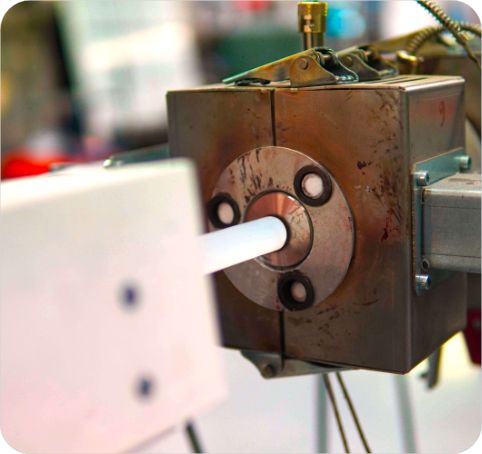

The transformation of the materials is done by compression molding, creep molding or extrusion to produce semi-finished products from powder.

These products are then machined by turning, milling or cutting. SPN possesses many industrial equipment to design and manufacture simple to complex part following the customers specification.

Finally, our teams manage all operations from design, manufacturing, assembly, inspection and packaging. We are certified ISO9001 and EN9100 to ensure that our process under control and provide long term know-how of our manufacturing process.

A question, a quote?

Do not hesitate to contact us at +33 (0) 1 48 45 49 79 or via this form: