ETFE Material (Éthylène tétrafluoroéthylène)

Key features:

- Excellent impact resistance

- Excellent resistance to stress cracking

- Density lower than PTFE

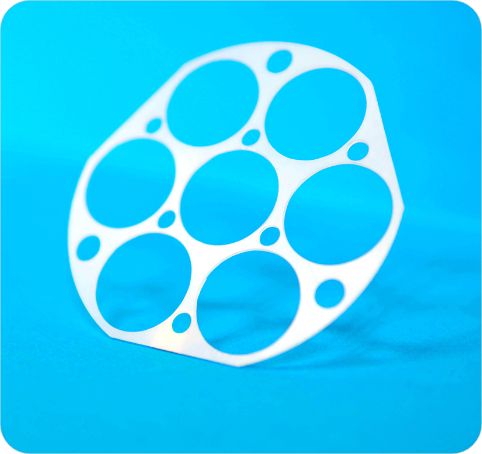

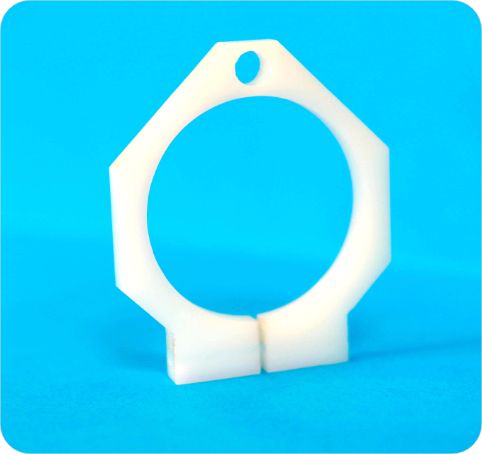

ETFE or Ethylene tetrafluoroethylene is a thermoplastic fluoropolymer used for good light transmission as well as for its resistance to gamma rays and UV rays.

ETFE has a very high impact and crack resistance which provides the ability to support a load 400 times greater than its weight. Semi-crystalline, this material is a preferred alternative to glass due to its good weather resistance, but also at a more affordable price. Lighter with a density of 1.7 – compared to 2.5 for glass -, ETFE also withstands changing temperatures from -80°C to 155°C, both high and low. This thermoplastic has excellent chemical resistance, even if it is lower than PTFE.

Also highly resistant to stress cracking, ETFE is one of the essential elements in the manufacture of injected mechanical assembly parts such as pumps, fittings or valves. It is also a material of choice in chemical industry applications due to its ability to retain its properties even when subjected to a very high temperature of 150°C and continuously. The fields of construction and architecture also use this plastic. It is used in particular in coating and joint manufacture. Easy to handle, but capable of transmitting light as well as glass, This polymer is widely used in building construction, especially in finishing.

The trade names of ETFE are: Tefzel® (Chemours), Fluon® (Asahi Glass Company), Neoflon® ETFE (Daikin), and Texlon® (Vector Foiltec).

Do you need more information? Contact us!

Our other materials

Need help finding your plastic?

Do not hesitate to use our search engine and our interactive pyramid.

A question, a quote?

Do not hesitate to contact us at +33 (0) 1 48 45 49 79 or via this form: