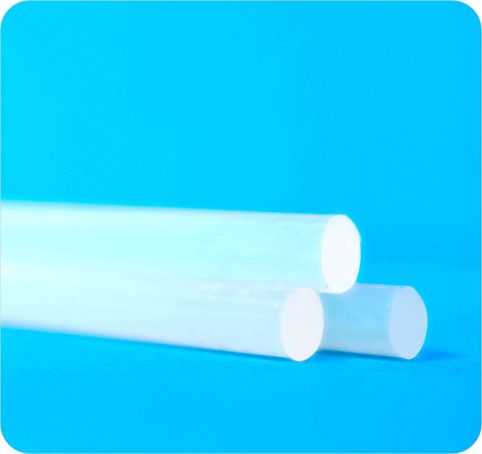

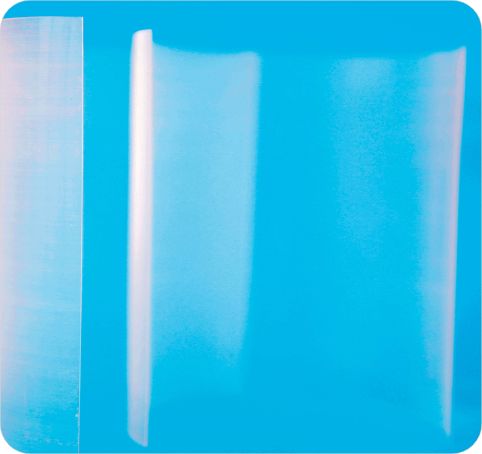

FEP Material (fluorinated ethylene propylene)

Key features:

- Almost perfect waterproofing

- Good chemical stability

- Resistant to cryogenic temperatures

FEP or fluorinated ethylene propylene is produced by polarized mixing of tetrafluoroethylene and hexafluoropropylene. This polymer can be processed in the molten state using compression, extrusion or injection molding techniques.

FEP is less resistant to wear, traction and creep than other fluorinated plastics. However, it is chemically inert with a low dielectric constant. Highly resistant to stress cracking, This plastic has a low friction coefficient and good thermal resistance, certainly lower than PTFE and PFA, but with an ability to maintain its mechanical properties after use at extreme temperatures from -270°C to 240°C.

This material resists and transmits Ultraviolet (UV) rays, especially UVC. It is often used with ultraviolet radiation lamps for various applications including the decontamination of pathogens (bacteria, viruses, etc.) on objects.

Non-hygroscopic with a moisture absorption of less than 0.01%, FEP is mainly used in the manufacture of pipes and equipment. Cable protection in aeronautics also requires the specific characteristics of this material. The manufacture of parts requiring a high degree of sealing, such as seals, also uses this type of thermoplastic.

Do you need more information? Contact us!

Our other materials

Need help finding your plastic?

Do not hesitate to use our search engine and our interactive pyramid.

A question, a quote?

Do not hesitate to contact us at +33 (0) 1 48 45 49 79 or via this form: