Plastic compression molding

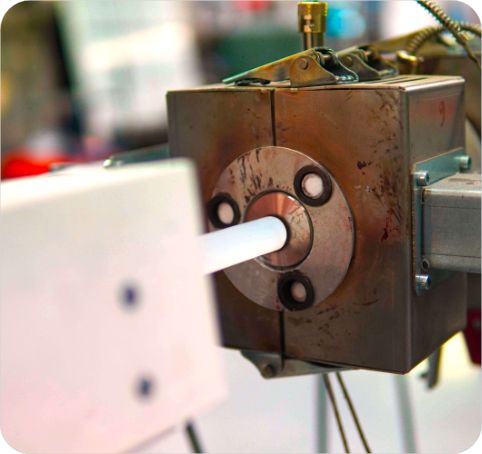

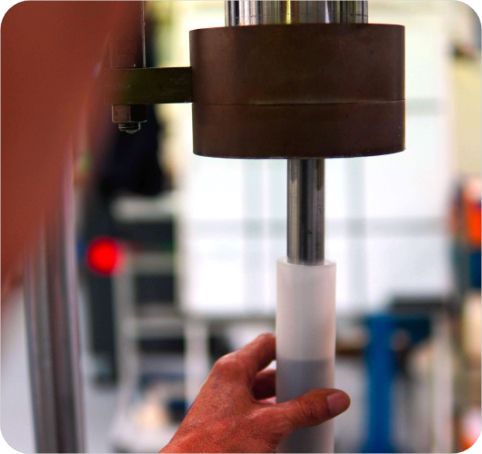

DEMGY SPN produces plastic compression moulding to manufacture blanks (semi-finished products). This process is based on the shaping, the heating and the compression of plastic materials. Compression can be at high temperature as for PCTFE (PTFCE / Voltalef / KEL-F) or standard temperature as for PTFE (charged or not). This process makes it possible to obtain semi-finished products such as rods, tubes or plates. Specific shapes are also compression-moulded according to customer designs.

Tubes are widely used to save material compared to solid bars and therefore have financial and environmental positive impact. DEMGY SPN has a large number of molds, including molds for tubes up to 500 mm in diameter. Our large number of molds enables us to chose the best fitting mold to match customer’s dimensions. These blanks are then machined internally or by our customers.

The manufacture of these drafts and one of DEMGY SPN’s specialities, particularly in the following materials:

- Polymers adapted to very low temperatures such as PCTFE / PTFCE, FEP ;

- Polymers resistant to very high temperatures, such as Polyimide (Vespel ®, or equivalent), PEI, PSU, PES ;

- Polymers used in contact with chemicals, such as PTFE, PFA, PVDF, FEP;

- Polymers chosen for their mechanical properties such as PEEK, ETFE, PPS.

Would you like more information on this process? Ask us!

A question, a quote?

Do not hesitate to contact us at +33 (0) 1 48 45 49 79 or via this form: