PCTFE film

PCTFE film

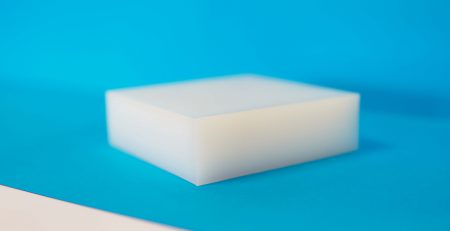

For more than 80 years SPN or Société des Plastiques Nobles has been working in the transformation and machining of high-performance plastics intended to be subjected to extreme conditions of heat and cold. Depending on customer requirements, SPN works with materials such as polyimide, PFA and PCTFE, one of the most widely used polymers in the cryogenics and aeronautics industries.

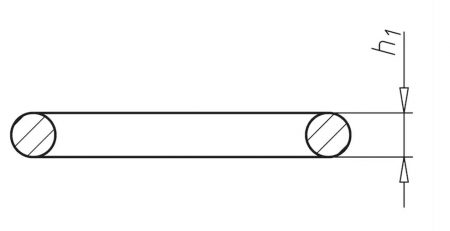

Société des Plastiques Nobles offers semi-finished products such as tubes and bars and machined parts such as valve seats and seals. SPN is also able to manufacture atypical components such as membranes, tapes and PCTFE films. Depending on customer requirements, the company produces prototypes of high-performance plastic components. SPN can also produce specific component models in PCTFE – or other high-performance plastics – either individually or in series.

Customized components such as PCTFE films are manufactured in the medical field, for example, to protect drugs from moisture. In order to ensure compliance with customer requirements and recommendations, these components are subject to various controls throughout the manufacturing and production process. To process and machine high-performance plastics, SPN uses a variety of processes including turning, milling and cutting.

Also known as polychlorotrifluoroethylene, PCTFE is best known for its ability to withstand extreme temperatures known as cryogenic. In addition to its chemical stability, this fluoropolymer has low gas permeability. It is also insensitive to attacks from antioxidants and certain active ingredients present in chemicals.