Extreme plastic material

Endowed with exceptional properties compatible with extremely difficult industrial environments, high performance plastic materials have many applications today. Société des Plastiques Nobles can help you find the right material for your extreme constraints (pressure, temperature, chemistry, wear, etc.)

High performance plastic materials, an excellent alternative to metal

High-performance plastic materials, commonly called “extreme plastic material”, have become the first choice for use in extreme conditions. Resistant to thermal oxidation, this type of material can be used in temperatures ranging from -273°C to nearly 300°C continuously. They can even withstand peak temperatures of 500°C while maintaining high mechanical strength. They also have excellent resistance to wear, friction with or without lubrication, and radiation. They are also known to have a low outgassing rate and a low moisture absorption rate. They also have the advantage of being inherently flame retardant and of being very good thermal and electrical insulators. Lighter than metal, but able to support heavy loads, “extreme plastic materials” have a lower manufacturing cost than ceramics.

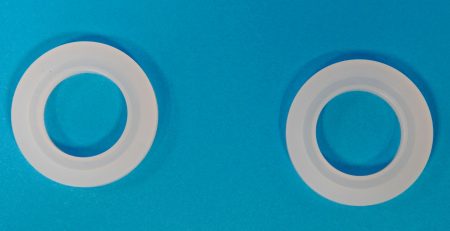

These polymers are therefore ideal for use in the most demanding industrial environments such as aeronautics, automotive, electrical and nuclear power generation, semiconductor processing and cryogenics. They can be used in the manufacture of bearings, insulators, thrust washers, bushings and wear rings, test sleeves, insert guides and pumps for various applications: water, chemicals and hydrocarbons. They are also prized as raw material for thermostatic injection molded parts and wear components for centrifugal pumps.

Let us create all your parts in engineering plastics

SPN has been processing and machining high-performance plastics for over 80 years. Our experience and know-how allow us to work with many technical polymers. You can entrust us with your needs for parts made of PTFE, PCTFE / PTFCE, PFA, POLYIMIDE Vespel®, FEP, ETFE, PVDF, PEEK, PSU, PPS, PAI or PEI.

We guarantee a full and complete satisfaction whether for prototypes or for mass production. We use different processes for a perfect customization of your parts and sub-assemblies. Depending on your specifications, we use compression molding, flow molding or extrusion for the transformation of high-performance plastics. Thanks to our numerous molds, we are able to produce your parts and sub-assemblies in the dimensions and shapes that suit your projects. For precision machining, we use specific machines for turning, milling and cutting. In addition, we also have at our disposal a CAM system that ensures a rapid design of your most complex elements.

In order to offer you quality services, we do not subcontract any of our operations. Thanks to our innovative machinery, our team takes care of everything: design, assembly, finishing, inspection, packaging and shipping.