The PFA at the service of the semiconductor industry

PFA or high purity perfluoroalkoxy is a material with properties inherited from PTFE and FEP. Thanks to its flexibility and clarity, PFA is the material of choice in laboratories and in the pharmaceutical industry, but it is also used in other technological areas. The wide temperature range from -200°C to +260°C, combined with the other qualities of PFA, makes it the ideal material for many applications in the semiconductor industry.

Products and accessories made from PFA used in the semiconductor industry are products that strictly meet all the requirements of the industry:

-

Fittings: various solutions for good fluid management for the most delicate applications. PFA fittings are generally products that always meet the requirements and standards of industries, including the semiconductor industry. High purity PFA fittings are usually injection molded. They can also be available in flared versions or in compression and butt weld configurations.

-

Specially designed dispensing and metering pumps are available for the transport of all kinds of liquids in the semiconductor industry. Pumps that are highly resistant to chemical corrosion. Made of high quality PFA, these pumps are easy to maintain and very practical: easy assembly and disassembly. As a general rule, PFA dispensing pumps are guaranteed free of metal and elastomer.

-

High-purity manifolds are indispensable accessories in the semiconductor industry, where delicate, highly corrosive chemicals are often used. These PFA manifolds are economical, space-saving and highly efficient, avoiding, among other things, leakage points.

-

A wide range of high-purity PFA valves that are based on state-of-the-art technology. Indispensable products for all applications involving the distribution of harmful and highly corrosive products in the semiconductor industry. High performance, reliable, pressure resistant and with improved flow, PFA valves meet all standards in the semiconductor industry. For increased productivity, they also reduce downtime.

-

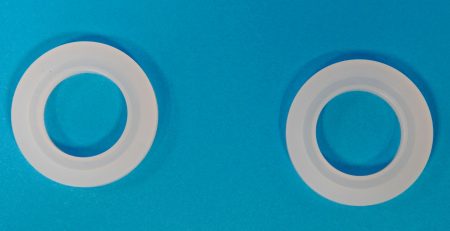

Various high-purity, always reliable, high-performance and robust PFA accessories can complement these different PFA products. These include pressure regulators, gauge protectors or static mixers. PFA accessories that further guarantee safety and productivity in the processing and handling of fluids.