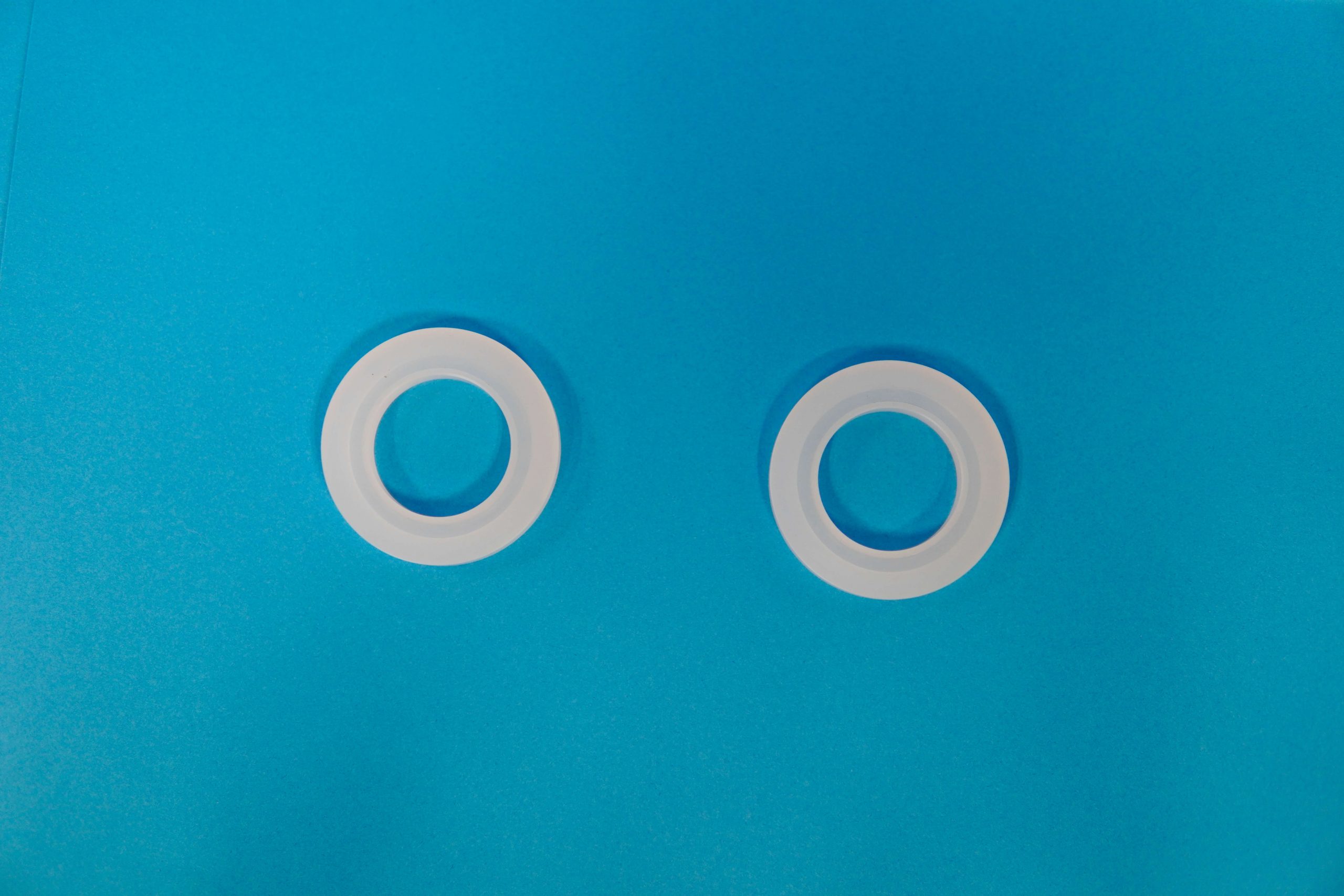

PTFE and PCTFE can be used as solid lubricant in cryogenics

Thanks to the particularly exceptional properties of polymers, they are often used as solid lubricants in the field of tribology, especially in cryogenic environments.

At atmospheric pressure, cryogenic fluids have very low viscosities. For liquid oxygen, the viscosity is 0.20-10-3Pa-s and for liquid nitrogen it is 0.16-10-3Pa-s [25]. This makes fluid lubrication unlikely to occur. On the other hand, if the cryogenic fluid reacts with the surface, only very slight lubrication could be observed. However, in other liquid environments, such as N2, H2 or He, reactions that help the appearance of surface films favorable to contact have not been observed [26].

On the contrary, when there is contact between metals, in the presence of cryogenic liquid, seizing can be observed, because there is no lubrication. In a neutral atmosphere or in a reducing atmosphere, film formation does not exist: therefore, there is no lubrication for contact. Nevertheless, cryogenic fluids have rather interesting properties to obtain a trouble-free contact. One of these is the high cooling capacity of cryogenic fluids. This makes it possible to get around the problems associated with the high heat generated by friction. [27].

In any case, many lubricants, such as oils, cannot be used at cryogenic temperatures. The risk of seizure can only be avoided with solid lubricants when working with cryogenic liquids. For this reason, PTFE (polytetrafluoroethylene) and MoS2 (molybdenum disulfide) are often used in this case [27]. Special attention is also paid to surface treatments that reduce the risk of seizure and friction [28].

All these uses have also been the subject of numerous studies, namely the thesis on the “Tribological behaviour of the PCTFE/steel 440C contact in nitrogen at cryogenic temperature”.

Sources :

J.-L. Bozet. Modelling of friction and wear for designing cryogenic valves. Tribology International, 34(4) :207 – 215, 2001.

[26] P. Adjadj. Influence du milieu cryotechnique sur le comportement tribologique des matériaux hétérogènes – Etude en glissement sec dans l’azote liquide. PhD thesis, Université

Paris 6, 1988.

[27] A. R. Lansdown. Low temperature lubrication. Technical report, Swansea Tribology Centre (for the European Space Agency), 1978.

[28] R. Gras. Etude de traitements de surface applicables sur les roulements cryotechniques.

Technical report, Convention S.E.P./I.S.M.C.M., n°523036, 1986.

[29] M. Fontanille and Y. Gnanou. Structure moléculaire et morphologie des polymères. Techniques de l’ingénieur, A 3 042 :1–28, 1994.

[30] G.M. Bartenev and V.V. Lavrentev. Chapter 1 : Structure and physical properties of

polymers. In Lieng-Huang Lee and K.C. Ludema, editors, Friction and Wear of Polymers,

volume 6 of Tribology Series, pages 1 – 29. Elsevier, 1981.