Polyvinylidene fluoride – PVDF

At SPN, we process and machine many high performance plastic materials. One of these materials is polyvinylidene fluoride, more commonly known as PVDF. A type of thermoplastic polymer with exceptional properties that allows us to manufacture parts for the most demanding sectors, particularly in the chemical industry.

Polyvinylidene fluoride: a high performance material

Polyvinylidene fluoride is a thermoplastic polymer that stands out for its remarkable resistance to chemical agents. PVDF is very resistant to the actions or aggressions of chemical products. Although polyvinylidene fluoride remains sensitive to ketones and esters, it is a material that resists well to many chemicals such as mineral acids and bases, aliphatic and aromatic hydrocarbons, halogenated solvents, chlorinated solvents or alcohols. In addition, PVDF is highly inert and its properties remain stable over a temperature range of -20°C to 130°C. Its intrinsic fire resistance properties only deteriorate above 175°C.

But other properties make this material even more useful. It has good UV and radiation resistance. It also has excellent mechanical properties including non-stick and gas impermeability. It has a high resistance to abrasion and aging. Thanks to all these properties, PVDF is used in many applications and in all sectors where reliability of critical parts is required. In the field of thermoplastic polymer processing, polyvinylidene fluoride is better known under the trade names Kynar® for Arkema, Solef® for Solvay and Dyneon® PVDF for 3M.

SPN masters the transformation of polyvinylidene fluoride

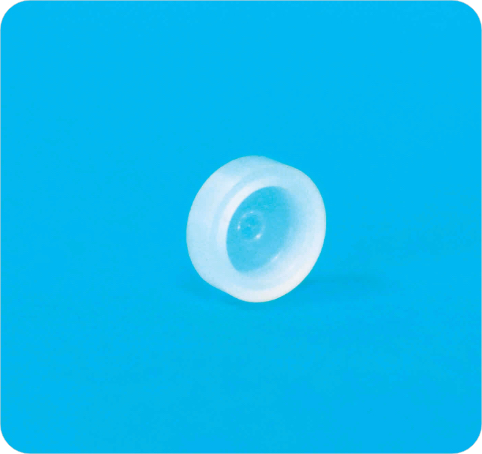

Thanks to its numerous transformation techniques, SPN is able to machine any part from polyvinylidene fluoride. Among others, PVDF can be transformed by molding, or by extrusion from granules. This allows SPN to design parts for the chemical, nuclear, medical, electrical and electronic industries. Most of these industries require extra chemical resistant materials such as PVDF for insulation, protective barriers, tube linings, tanks, piping and tubing of all kinds.

SPN is an expert in the machining and processing of various high performance plastic materials including PVDF. For several years, SPN has been manufacturing standard parts as well as custom-made parts, even specific ones. For the manufacture of parts, we use a computer-assisted manufacturing process. Depending on the technical characteristics of the product, we choose the best and most suitable manufacturing process. The parts we manufacture meet all the requirements of your sector of activity and the content of your specifications. To learn more about our services and products, we invite you to contact our team.