PFA molding

Information on the PFA molding at SPN

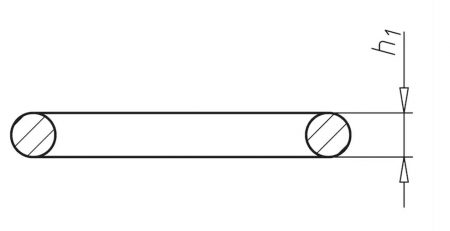

SPN carries out PFA compression molding operations for the manufacture of your blanks. This process enables us to offer all types of semi-finished products such as PFA bars, tubes and plates or other specific shapes according to customer specifications. The material is inserted into a mold. It is then put in an oven to raise its temperature according to precise parameters. Once the mold and the material are at the right temperature, the mold is placed under a press and is compressed while it cools down. This process allows a slow and controlled cooling for an optimal quality.

Our molding operations are obtained thanks to a large number of molds and allow us to offer parts that are faithful to the desired dimensions. Our tubes are economical and more environmentally friendly than solid bars and save a significant amount of material. They can then be machined by our team or by the customer.

These blanks can be made in many materials, including PFA or perfluoroalkoxy. Its properties, similar to those of PTFE, offer high heat resistance with a wide temperature range (from -220 °C up to 260 °C). It also offers outstanding chemical resistance just like PTFE. It is unaffected by acids, ketones, bases, hydrocarbons and alcohols and has other notable characteristics such as a low dielectric constant, perfect resistance to UV radiation and almost zero moisture absorption capacity.

PFA can be compression molded, but also extruded or pulled (e.g. in the manufacture of pipes or tubes). It is used in various industries such as the semiconductor industry, the pharmaceutical industry but also in fluid treatment processes. It is also frequently used for electrical applications or for coatings subject to hostile environments combining specific chemical, mechanical or thermal constraints.