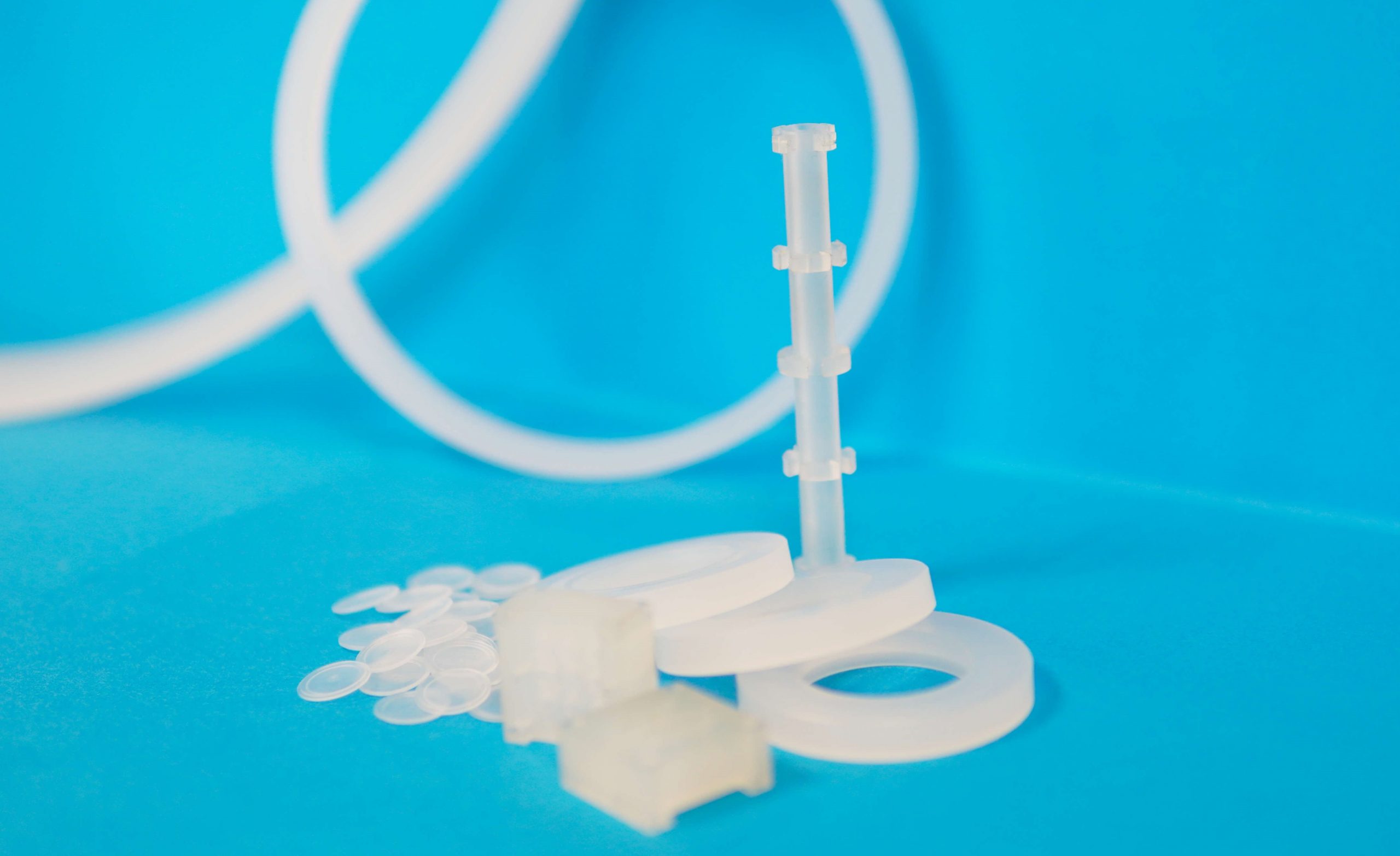

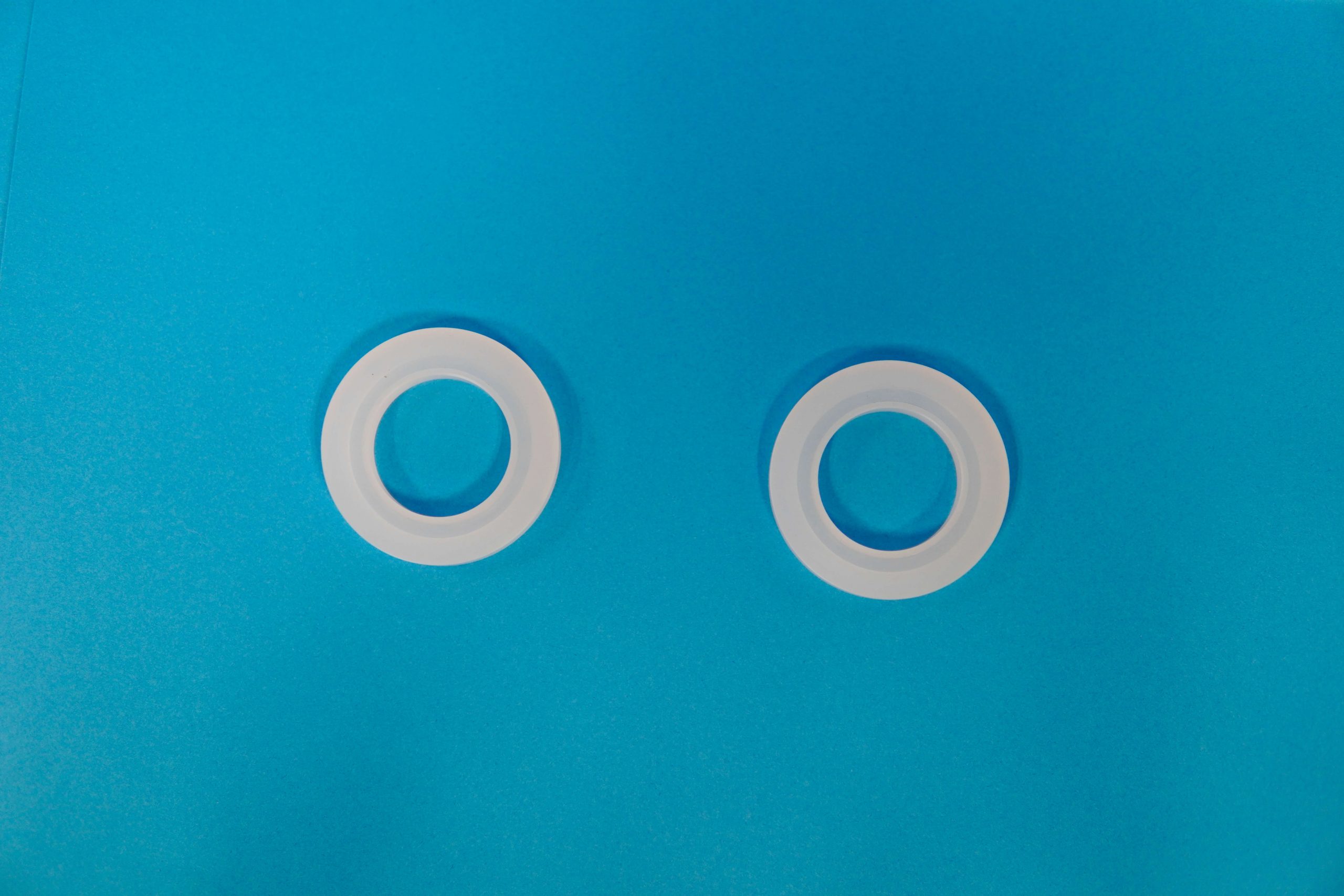

Presentation of the Kel-F brand – KEL-F81

The name Kel-F81®, from MW Kellogg's company, came into being after the Second World War. It is an abbreviation of the name "Kellogg" and "fluoropolymer" for PCTFE material. It was acquired by 3M Company in 1957, but the company discontinued manufacturing Kel-F® in 1996. Currently, the Kel-F® brand remains...