PCTFE vs PTFE

PCTFE vs PTFE

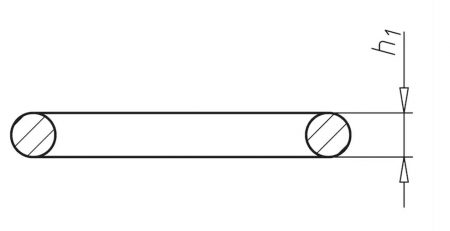

PCTFE and PTFE are two fluoropolymers with similar chemical formulas. PCTFE is a derivative of PTFE composed of an additional chlorine atom. This atom is responsible for the low melt index of PCTFE. The coefficient of thermal expansion of PCTFE is also low compared to that of PTFE. The material is able to maintain good dimensional stability even when subjected to temperatures ranging from – 240 °C to + 150 °C.

In industrial sectors such as cryogenics and high-performance valves, PCTFE is considered a true material of choice. This fluoropolymer has the best technical characteristics. In addition to its low gas permeability, PCTFE is highly resistant to very low or even cryogenic temperatures. This polymer also has good chemical stability. Unlike PTFE, it has good tensile strength and creep resistance. PCTFE stands out for its excellent flammability resistance. Free of hydrogen atoms, this material resists well to the attacks of oxidizing agents and certain active ingredients contained in chemical products. It is widely used for high pressure valve seals. It has an insensitivity and a good transmission to UVC.

PTFE or polytetrafluoroethylene fluoropolymer is also a material of choice. It is much more common (often referred to by the brand name Teflon). Manufacturers use it for the manufacture of elements that are both insensitive to UV rays and non-toxic at the same time. Non-flammable, this material resists well to humidity. It retains its stability and properties even when exposed to temperatures ranging from -80°C to + 250°C. PTFE can be filled with fibreglass, carbon, bronze and graphite. These additional components optimise its basic properties.