PSU molding

Information on the PSU molding at SPN

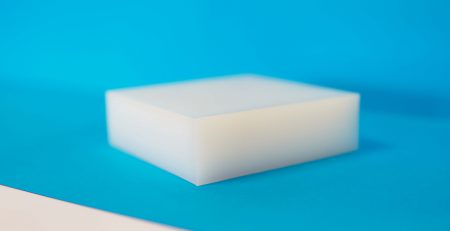

The moulding of plastic material to make blanks is one of the activities for which SPN is renowned, particularly in the field of PSU (Polysulfone). Compression moulding allows the production of various semi-finished products such as tubes, plates and bars. The designs as well as the proposed dimensions are variable according to the customer’s needs.

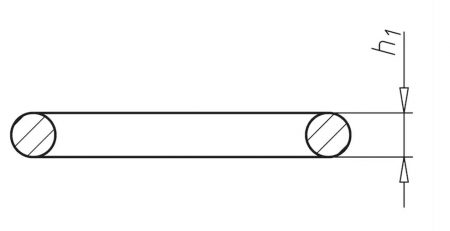

Tubes are among the most popular shapes requested by customers. Their manufacture allows to optimize the amount of material required, especially for large joints. In addition to the reduced manufacturing cost, the environmental impact is also reduced. For several years, SPN has been striving to always satisfy the requirements of its customers. To this end, the company has equipped itself with moulds for tubes with different diameters. The company is even able to offer moulds with a diameter of up to 500 mm.

In addition to its resistance and dimensional stability at high temperatures, PSU or Polysulfone has several other qualities. It is very resistant to creep. This thermoplastic is also known for its ability to withstand bending and tensile stress. The material is impermeable and can be steam sterilized. PSU is an excellent electrical insulator and is resistant to infrared and microwave radiation as well as gamma and beta radiation. Paraffin oils as well as alkalis and organic acids have no effect on the PSU.