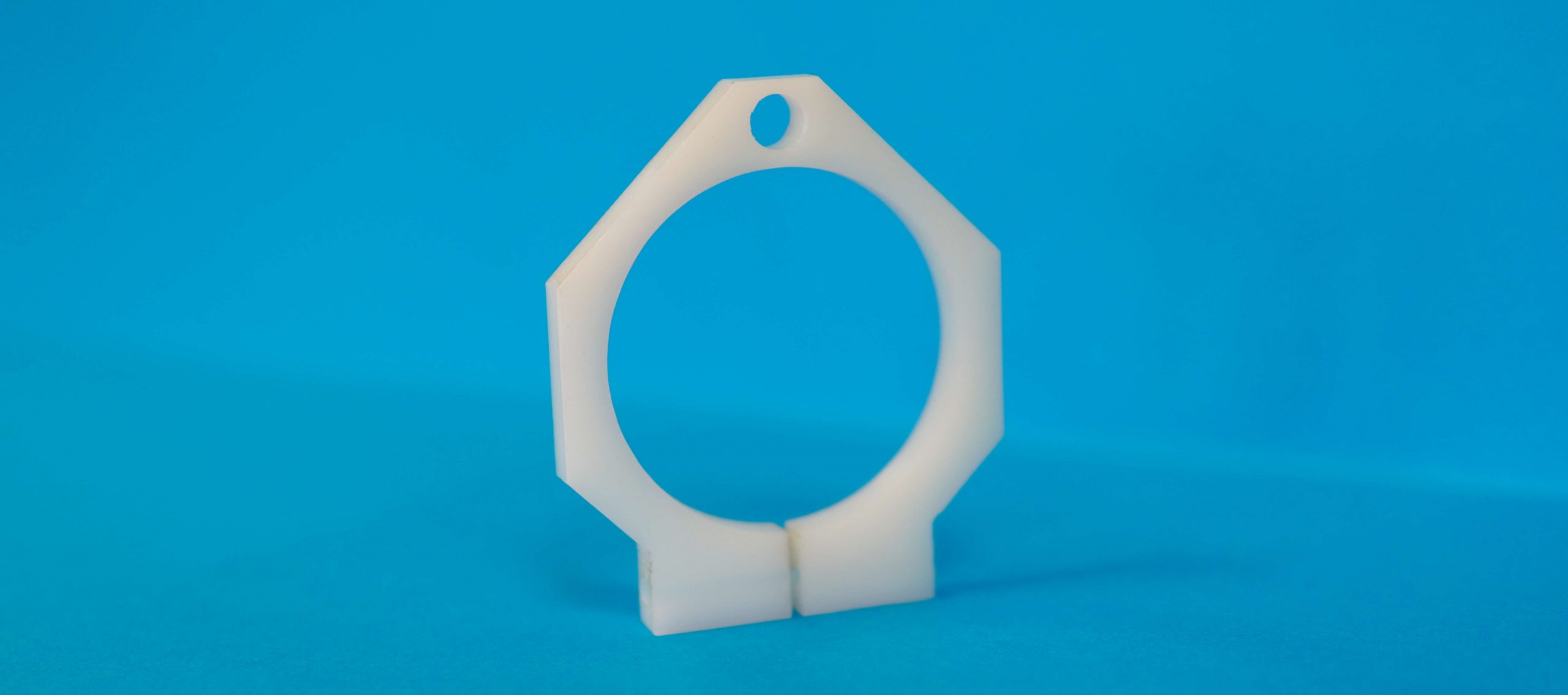

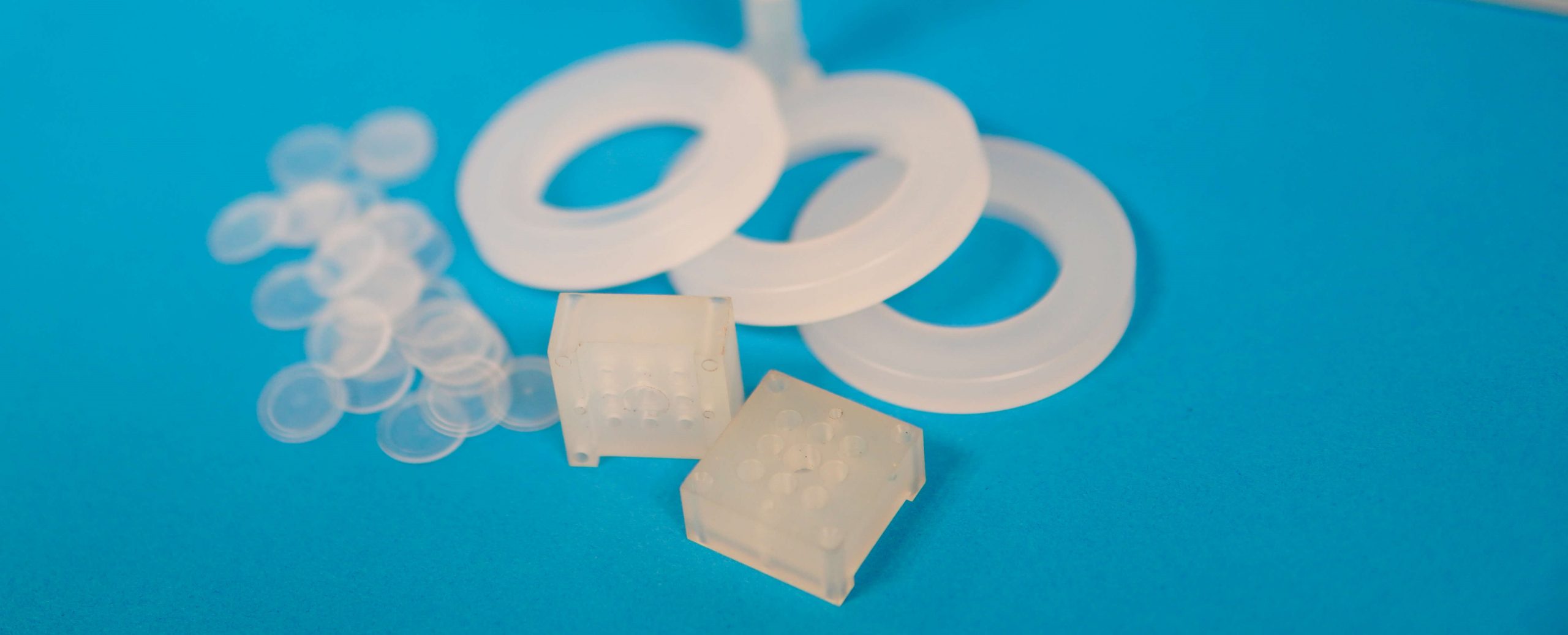

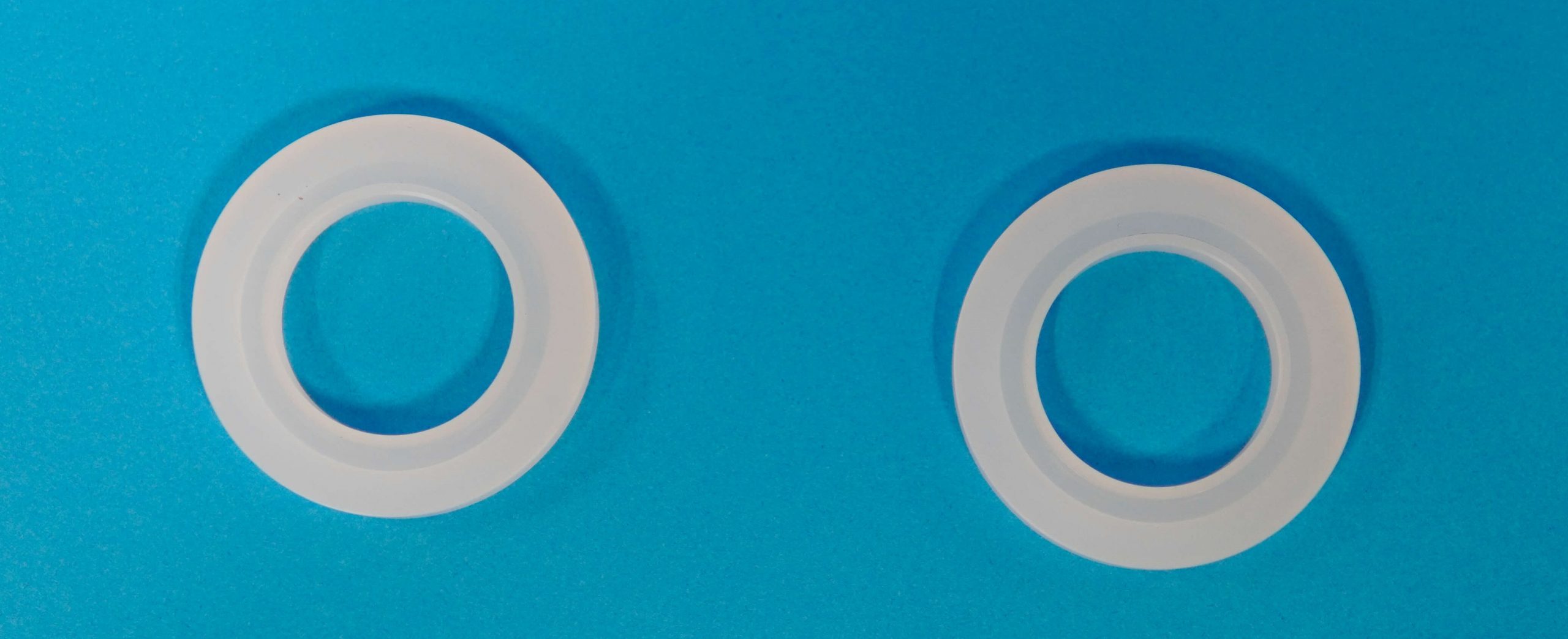

Tefzel

Tefzel™ is a brand of ETFE or ethylene tetrafluoroethylene resins produced by Dupont. This material is also known under the brand names Neoflon® ETFE by Daikin, Fluon® by Asahi Glass Company, and Texlon® by Vector Foiltec. This thermoplastic fluoropolymer is widely used in the building industry and is appreciated...